How do the properties of different materials affect the printability and visual appeal of mailer boxes?

The properties of different materials significantly influence the printability and visual appeal of mailer boxes. These factors determine how well the material can be printed on, the quality of the printed graphics, and the overall aesthetic of the box. Below is a detailed analysis of how these properties impact the printability and visual appeal of mailer boxes:

Impact on Printability: Smooth surfaces, like coated paper, provide a uniform area for high-quality printing, resulting in sharp and vivid images. Rough surfaces, like uncoated cardboard, cause ink to spread unevenly, leading to a grainy appearance.

Impact on Visual Appeal: Smooth surfaces create a sleek, professional look suitable for detailed graphics, while textured surfaces give a rustic or eco-friendly appeal.

Impact on Printability: Bright, light-colored materials, such as bleached kraft paper, enhance the vibrancy of printed colors. Dark or natural brown materials can dull colors, often requiring a white base coat for proper color representation.

Impact on Visual Appeal: Bright materials support vivid, eye-catching designs, while darker tones provide a natural, environmentally conscious aesthetic.

Impact on Printability: Glossy coatings enhance color vibrancy and detail, while matte finishes offer a softer look and better fingerprint resistance. Each finish affects the clarity and quality of printed designs.

Impact on Visual Appeal: Glossy surfaces create a shiny, premium look, ideal for high-end products, whereas matte finishes provide a subtle, elegant appearance, suitable for luxury items.

Impact on Printability: Low-porosity materials, like coated paper, allow for sharp, vibrant prints with minimal ink absorption. High-porosity materials, such as uncoated cardboard, absorb more ink, leading to blurred images and muted colors.

Impact on Visual Appeal: Low-porosity materials maintain print quality and vibrant colors, while high-porosity materials offer a textured, artisanal look that may appeal to certain brands.

Impact on Printability: Thicker materials, such as corrugated cardboard, support more ink and complex designs without warping. Thinner materials, like lightweight paperboard, are easier to print on but may lack durability.

Impact on Visual Appeal: Thick materials convey robustness and quality, ideal for protective packaging, while thinner materials offer a cost-effective option for visually appealing, lighter packaging.

By understanding how these material properties affect the printability and visual appeal of mailer boxes, manufacturers and designers can make informed decisions to create effective and attractive packaging solutions that meet the needs of both the brand and the consumer.

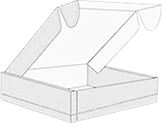

What structural features are essential for paper mailer boxes?

Structural features play a crucial role in ensuring that paper mailer boxes are effective in protecting their contents during shipping and handling. Here are some essential structural features that are important for paper mailer boxes:

Box Construction:

Rigid Walls: Sturdy and rigid walls help maintain the shape of the box and provide protection against external impacts and pressure.

Secure Closure: A reliable closure mechanism, such as self-sealing adhesive strips or interlocking tabs, ensures that the box remains securely closed throughout the shipping process.

Corner and Edge Protection:

Corner Reinforcements: Reinforced corners with additional layers or inserts protect vulnerable areas from impact and crushing, especially during stacking or rough handling.

Edge Crush Resistance: Enhanced resistance along the edges prevents the box from collapsing or bulging under pressure, maintaining its structural integrity.

Internal Cushioning and Support:

Padding and Inserts: Internal cushioning materials, such as bubble wrap, foam inserts, or corrugated dividers, provide shock absorption and prevent items from shifting inside the box.

Support Structures: Sturdy cardboard inserts or partitions help support and separate multiple items within the box, reducing the risk of damage during transit.

Sealing and Security Features:

Tamper-Evident Seals: Tamper-evident seals or tapes provide reassurance that the box has not been opened or tampered with during shipment.

Water Resistance: Coatings or laminations that provide water resistance can protect the contents from moisture during transit and storage.

Stackability and Handling Considerations:

Stacking Strength: Boxes designed with reinforced bottoms and top flaps enhance stacking strength, allowing them to withstand the weight of other packages without crushing.

Easy Handling: Ergonomic features, such as integrated handles or grip areas, facilitate easy lifting and carrying, reducing the risk of mishandling or dropping.

Customizable Design:

Scalability: Modular designs that can be easily resized or adjusted to accommodate different product sizes and shapes.

Brand Customization: Customizable printing options for branding and promotional purposes, enhancing the box's aesthetic appeal and brand recognition.

These structural features collectively ensure that paper mailer boxes not only provide adequate protection for their contents but also enhance the overall customer experience by safeguarding the integrity of shipped items from packaging to delivery.

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

中文简体

中文简体