-

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

Hangzhou Shengpin Packaging Co., Ltd. is a comprehensive printing and packaging enterprise that provides diversified, one-stop services including graphic design, CTP plate making, color printing, and packaging production. At present, the company's business scope has covered color boxes, color boxes, corrugated boxes, cartons, window boxes, display boxes, display stands, etc., and can provide customers with highly competitive packaging solutions.

| Item | Packaging box |

| Material | Corrugated board / cardboard / grey cardboard / art paper / coated paper / kraft paper / fancy paper etc. |

| Size | Customised |

| Artwork | PDF or AI, PDF is preferred |

| Printing mode | Offset printing |

| Color | CMYK / pantone color / custom color |

| Surface treatment | Lamination / stamping / UV / varnishing / embossing / debossing etc. |

| Insert | Cardboard / plastic / EVA / sponge / molded pulp / with satin etc. |

| Sample time | 7 days |

| Lead time | 7-15 days |

| MOQ | 500 |

| Shipment | By sea / air / land / multimodal transport |

| Origin | Hangzhou, China / Suzhou, China |

| Brand | Shengpin packing |

| Packing | Carton |

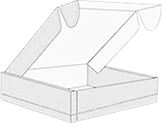

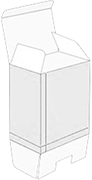

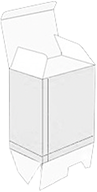

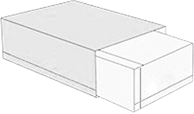

Made of corrugated board or white/grey cardboard, packaging boxes can be designed into various types. Generally, mailer box, snaplock bottom, auto bottom, tuck end, seal-end general box, hanger box, drawer box, pillow box, house-shaped box are the common ones and all of them are collapsible and easy to be shipped and stored. Whether it’s for cosmetics, 3C products, food & beverage, clothing, stationery or any other products in life, one can always find the proper type of box for their commodity. As long as an artwork design can be provided, all types of packaging boxes can be manufactured at Shengpin Packing.

When the commodity is fragile or it’s a set of products, an insert is needed for packaging, which can fix the commodity and prevent it from being damaged due to collision. Wine, 3C commodities, skincare set, toy set and other set products are normally packed with an insert. According to the material, cardboard, plastic, EVA, sponge, satin and molded pulp are the frequently used ones. Plastic insert is the popular one in the past as it’s cheap and easy to produce. With environmental awareness increased, eco-friendly material like cardboard becomes more and more popular.

To increase the firmness, the surface of packaging box and display stand is usually gloss laminated, matte laminated or varnished depending on the effect to achieve. That’s a kind of treatment for the whole surface. On some other occasions, part of the surface needs to be highlighted. In this circumstance, spot UV, foil/silver stamping, debossing and embossing are the main techniques. It’s usually used to make the company name, logo or an image to stand out on the packaging box or display stand. No matter it’s whole surface or partial surface treatment, it can help improve the product quality.

Hangzhou Shengpin Packaging Co., Ltd. is professional China paper mailer boxes manufacturers and mailer boxes factory, established in 2012. It is a professional paper packaging enterprise integrating graphic design, CTP plate making, offset printing, package production, and other diversified services.

With quick business expansion and in order to meet clients’ needs, another production base Anhui Shengpin Printing and Packaging Co., Ltd. was founded in Huixian Economic Development Zone, Suzhou City, Anhui Province in 2021. It covers an area of 50 acres and is equipped with high-end printing and packaging facilities like Heidelberg, Manroland, Kodak, and other famous brands. Therefore, all production can be strictly kept under control from beginning to end in-house. Quality control can be well guaranteed.

Shengpin Packaging specializes in manufacturing foldable paper products like mailer boxes, auto bottom boxes, snaplock bottom boxes, tuck-end boxes, seal-end boxes, and hanger boxes as well as cardboard display stands and boxes. Those products can be widely used in various industries eg. food and drinks, clothing, textile, stationery, skincare, home appliances, tools, and toys. Almost all aspects of life are related to paper packaging as it’s cost-saving and eco-friendly.

We have cooperated with many big brands in China and are continuously working with them due to our stable quality and competitive prices. May our services can be recognized by more and more clients home and abroad.

How do the properties of different materials affect the printability and visual appeal of mailer boxes?

The properties of different materials significantly influence the printability and visual appeal of mailer boxes. These factors determine how well the material can be printed on, the quality of the printed graphics, and the overall aesthetic of the box. Below is a detailed analysis of how these properties impact the printability and visual appeal of mailer boxes:

Impact on Printability: Smooth surfaces, like coated paper, provide a uniform area for high-quality printing, resulting in sharp and vivid images. Rough surfaces, like uncoated cardboard, cause ink to spread unevenly, leading to a grainy appearance.

Impact on Visual Appeal: Smooth surfaces create a sleek, professional look suitable for detailed graphics, while textured surfaces give a rustic or eco-friendly appeal.

Impact on Printability: Bright, light-colored materials, such as bleached kraft paper, enhance the vibrancy of printed colors. Dark or natural brown materials can dull colors, often requiring a white base coat for proper color representation.

Impact on Visual Appeal: Bright materials support vivid, eye-catching designs, while darker tones provide a natural, environmentally conscious aesthetic.

Impact on Printability: Glossy coatings enhance color vibrancy and detail, while matte finishes offer a softer look and better fingerprint resistance. Each finish affects the clarity and quality of printed designs.

Impact on Visual Appeal: Glossy surfaces create a shiny, premium look, ideal for high-end products, whereas matte finishes provide a subtle, elegant appearance, suitable for luxury items.

Impact on Printability: Low-porosity materials, like coated paper, allow for sharp, vibrant prints with minimal ink absorption. High-porosity materials, such as uncoated cardboard, absorb more ink, leading to blurred images and muted colors.

Impact on Visual Appeal: Low-porosity materials maintain print quality and vibrant colors, while high-porosity materials offer a textured, artisanal look that may appeal to certain brands.

Impact on Printability: Thicker materials, such as corrugated cardboard, support more ink and complex designs without warping. Thinner materials, like lightweight paperboard, are easier to print on but may lack durability.

Impact on Visual Appeal: Thick materials convey robustness and quality, ideal for protective packaging, while thinner materials offer a cost-effective option for visually appealing, lighter packaging.

By understanding how these material properties affect the printability and visual appeal of mailer boxes, manufacturers and designers can make informed decisions to create effective and attractive packaging solutions that meet the needs of both the brand and the consumer.

What structural features are essential for paper mailer boxes?

Structural features play a crucial role in ensuring that paper mailer boxes are effective in protecting their contents during shipping and handling. Here are some essential structural features that are important for paper mailer boxes:

Box Construction:

Rigid Walls: Sturdy and rigid walls help maintain the shape of the box and provide protection against external impacts and pressure.

Secure Closure: A reliable closure mechanism, such as self-sealing adhesive strips or interlocking tabs, ensures that the box remains securely closed throughout the shipping process.

Corner and Edge Protection:

Corner Reinforcements: Reinforced corners with additional layers or inserts protect vulnerable areas from impact and crushing, especially during stacking or rough handling.

Edge Crush Resistance: Enhanced resistance along the edges prevents the box from collapsing or bulging under pressure, maintaining its structural integrity.

Internal Cushioning and Support:

Padding and Inserts: Internal cushioning materials, such as bubble wrap, foam inserts, or corrugated dividers, provide shock absorption and prevent items from shifting inside the box.

Support Structures: Sturdy cardboard inserts or partitions help support and separate multiple items within the box, reducing the risk of damage during transit.

Sealing and Security Features:

Tamper-Evident Seals: Tamper-evident seals or tapes provide reassurance that the box has not been opened or tampered with during shipment.

Water Resistance: Coatings or laminations that provide water resistance can protect the contents from moisture during transit and storage.

Stackability and Handling Considerations:

Stacking Strength: Boxes designed with reinforced bottoms and top flaps enhance stacking strength, allowing them to withstand the weight of other packages without crushing.

Easy Handling: Ergonomic features, such as integrated handles or grip areas, facilitate easy lifting and carrying, reducing the risk of mishandling or dropping.

Customizable Design:

Scalability: Modular designs that can be easily resized or adjusted to accommodate different product sizes and shapes.

Brand Customization: Customizable printing options for branding and promotional purposes, enhancing the box's aesthetic appeal and brand recognition.

These structural features collectively ensure that paper mailer boxes not only provide adequate protection for their contents but also enhance the overall customer experience by safeguarding the integrity of shipped items from packaging to delivery.