-

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

| Item | Packaging box |

| Material | Corrugated board / cardboard / grey cardboard / art paper / coated paper / kraft paper / fancy paper etc. |

| Size | Customised |

| Artwork | PDF or AI, PDF is preferred |

| Printing mode | Offset printing |

| Color | CMYK / pantone color / custom color |

| Surface treatment | Lamination / stamping / UV / varnishing / embossing / debossing etc. |

| Insert | Cardboard / plastic / EVA / sponge / molded pulp / with satin etc. |

| Sample time | 7 days |

| Lead time | 7-15 days |

| MOQ | 500 |

| Shipment | By sea / air / land / multimodal transport |

| Origin | Hangzhou, China / Suzhou, China |

| Brand | Shengpin packing |

| Packing | Carton |

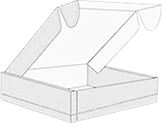

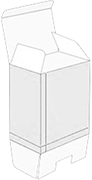

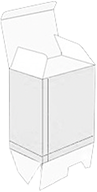

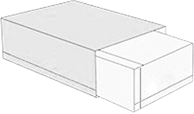

Made of corrugated board or white/grey cardboard, packaging boxes can be designed into various types. Generally, mailer box, snaplock bottom, auto bottom, tuck end, seal-end general box, hanger box, drawer box, pillow box, house-shaped box are the common ones and all of them are collapsible and easy to be shipped and stored. Whether it’s for cosmetics, 3C products, food & beverage, clothing, stationery or any other products in life, one can always find the proper type of box for their commodity. As long as an artwork design can be provided, all types of packaging boxes can be manufactured at Shengpin Packing.

When the commodity is fragile or it’s a set of products, an insert is needed for packaging, which can fix the commodity and prevent it from being damaged due to collision. Wine, 3C commodities, skincare set, toy set and other set products are normally packed with an insert. According to the material, cardboard, plastic, EVA, sponge, satin and molded pulp are the frequently used ones. Plastic insert is the popular one in the past as it’s cheap and easy to produce. With environmental awareness increased, eco-friendly material like cardboard becomes more and more popular.

To increase the firmness, the surface of packaging box and display stand is usually gloss laminated, matte laminated or varnished depending on the effect to achieve. That’s a kind of treatment for the whole surface. On some other occasions, part of the surface needs to be highlighted. In this circumstance, spot UV, foil/silver stamping, debossing and embossing are the main techniques. It’s usually used to make the company name, logo or an image to stand out on the packaging box or display stand. No matter it’s whole surface or partial surface treatment, it can help improve the product quality.

Compared to traditional plastic material packaging, more and more companies choose to use paper boxes for packaging as it’s cost-effective and eco-friendly. Corrugated board, cardboard, grey board, kraft as well as fancy paper are the main materials for packaging boxes; among which, corrugated board is the frequently used one.

Corrugated boards can be divided into several series according to the layer thickness.

For cardboard, greyboard and Kraft paper, 250gsm/300gsm/350gsm/400gsm paper are the commonly used ones. These boxes are usually used for skincare, stationery, toys, and other relatively small items. Cardboard especially Kraft paper generally used for high-end products due to its cost. The natural texture and scent of the Kraft paper make it favorable for some premium commodities producers. Fancy paper is the costly paper material that’s usually used for luxury goods.

Shengpin specializes in manufacturing packaging boxes and has provided clients with meticulous services on this.

Hangzhou Shengpin Packaging Co., Ltd. is professional China corrugated packaging boxes manufacturers and cardboard packaging boxes factory, established in 2012. It is a professional paper packaging enterprise integrating graphic design, CTP plate making, offset printing, package production, and other diversified services.

With quick business expansion and in order to meet clients’ needs, another production base Anhui Shengpin Printing and Packaging Co., Ltd. was founded in Huixian Economic Development Zone, Suzhou City, Anhui Province in 2021. It covers an area of 50 acres and is equipped with high-end printing and packaging facilities like Heidelberg, Manroland, Kodak, and other famous brands. Therefore, all production can be strictly kept under control from beginning to end in-house. Quality control can be well guaranteed.

Shengpin Packaging specializes in manufacturing foldable paper products like mailer boxes, auto bottom boxes, snaplock bottom boxes, tuck-end boxes, seal-end boxes, and hanger boxes as well as cardboard display stands and boxes. Those products can be widely used in various industries eg. food and drinks, clothing, textile, stationery, skincare, home appliances, tools, and toys. Almost all aspects of life are related to paper packaging as it’s cost-saving and eco-friendly.

We have cooperated with many big brands in China and are continuously working with them due to our stable quality and competitive prices. May our services can be recognized by more and more clients home and abroad.

2025-03-04

What Are the Key Factors That Influence the Selection of Materials for Drinks Packaging Boxes in Terms of Safety, Cost, and Environmental Impact? The selection of materials for drinks packaging boxes is a critical decision in the beverage industry, as it affects not only the ... Read MoreIn what aspects is the sustainability of cardboard/corrugated packaging boxes?

The sustainability of cardboard/corrugated packaging boxes is reflected in the following aspects:

Renewable resources: Cardboard and corrugated board are made from renewable resources and are often recyclable, making them an environmentally friendly packaging solution.

Recycling: Cardboard and corrugated cardboard can be recycled, which helps reduce waste and the need for new raw materials.

Waste reduction: Cardboard and corrugated board can be designed to minimize material usage, which helps reduce waste and increase efficiency.

Reduce transportation costs: Cardboard and corrugated cardboard are lighter than other packaging materials, which helps reduce transportation costs and reduce the carbon footprint during transportation.

Reduced energy consumption: The production of paperboard and corrugated board generally requires less energy than other packaging materials, which helps reduce energy consumption and greenhouse gas emissions.

Biodegradability: Cardboard and corrugated cardboard are biodegradable, which means they break down naturally, reducing waste.

Reduced environmental impact: The production of paperboard and corrugated board generally involves fewer chemicals and pollutants, which helps reduce environmental impact.

Compostability: Some cardboard and corrugated cardboard can be designed to be compostable, meaning they can be composted safely, reducing waste.

Renewable energy: Some paperboard and corrugated cardboard manufacturers use renewable energy, such as wind or solar power, to produce their products, which helps reduce greenhouse gas emissions.

Responsible forestry practices: Many cardboard and corrugated board manufacturers use wood from sustainably managed forests, which helps ensure the health of forests and the protection of biodiversity.

What is the reason why the material of cardboard/corrugated packaging boxes is relatively light?

Cardboard/corrugated packaging boxes are relatively lightweight materials. Here are some reasons:

Made from pulp: Cardboard and corrugated board are made from pulp, a material made from wood pulp or other plant fibers. Pulp is a lightweight material, which makes cardboard and corrugated board relatively lightweight as well.

Low Density: Cardboard and corrugated cardboard have relatively low densities, which means they have less mass in a given volume. This helps make them a lightweight packaging solution.

Corrugated Structure: The corrugated structure of corrugated cardboard provides additional strength and rigidity while keeping the material lightweight. This structure helps disperse forces, allowing the box to bear more weight without significantly adding to its own weight.

Customizable thickness: The thickness of cardboard and corrugated board can be customized according to specific packaging needs. Thinner materials provide the protection needed while maintaining lightness.

Lamination Technology: Cardboard and corrugated board can be combined with other materials (such as plastic film) through lamination technology to provide additional protection and functionality while still maintaining lightweight.

Foldable design: Cardboard and corrugated cardboard can be designed to be foldable, which helps reduce the volume and weight of the packaging while making it easier to transport and store.

Reduced material usage: Cardboard and corrugated board can be designed to minimize material usage, which helps reduce the overall weight of the package.